Welcome in BUP Utensili

B.U.P. Utensili was founded in 1968 and following the expansion of the local furniture manufactures started his own production of woodworking tools.

The hard work and determination meant that the company soon increased his output and were able to take on staff and to develop his technology so that it could corner a larger share of the market. In 1978 the company moved into new premises and could consider itself a full-blown industry, with 1300 square metres and 15 factory workers. After ten years in the business there was a real boom: sales increased and the market could now be expanded. Rather than simply working with local companies, as they had done in the beginning, they began to sell both to the rest of Italy and abroad. Their high quality products were very much in demand: B.U.P. Utensili soon became an important point of reference for many companies.

Experience in design and manufacturing

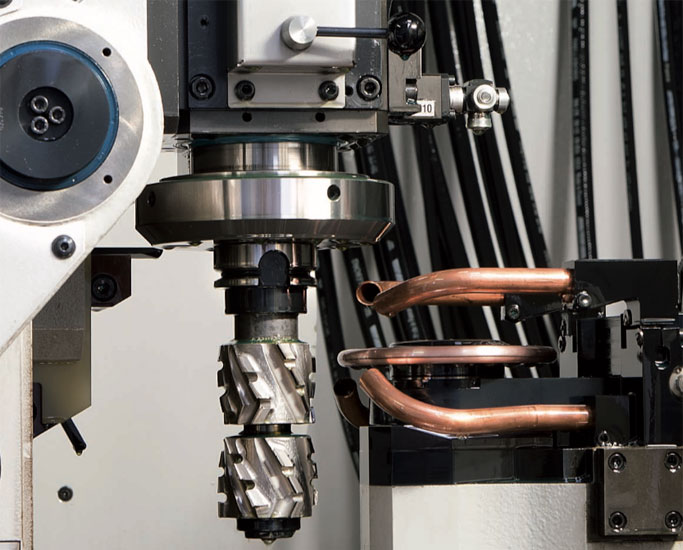

Today, the technology which is used to make tools takes advantage of state-of-the-art equipment.

First it is designed and plotted on computers using the graphics software CAD and CAD/CAM. This makes it possible to work on the designs in 3D and the graphic design of the cutter can be directly transmitted to the numerically controlled work stations which can then produce high quality products. Knives are made using two automatic profile machines with an automatic feeder. They have four different diamond wheels which can grind down the edges, finish, sharpen, and give super finishes to the raw material in HM. So that almost any type of shape is possible. B.U.P. Utensili specialises in making diamond tools. The production include a wide range of standard tools and also a lot of special products made upon customer specifications. This work cycle is completed by carrying out careful tests on the tool to check its precision: the test on wood is the final test that guarantees its high quality.

Over the years they have also gained a good deal of experience making tools for routers. They can meet specific detailed requests and make precise customised products for clients. This is one of their key selling points and one of the things they are most famous for.

Quality and efficiency

Their continual investment into high-tech machinery and in specially skilled technicians means that they can produce many different types of tools.

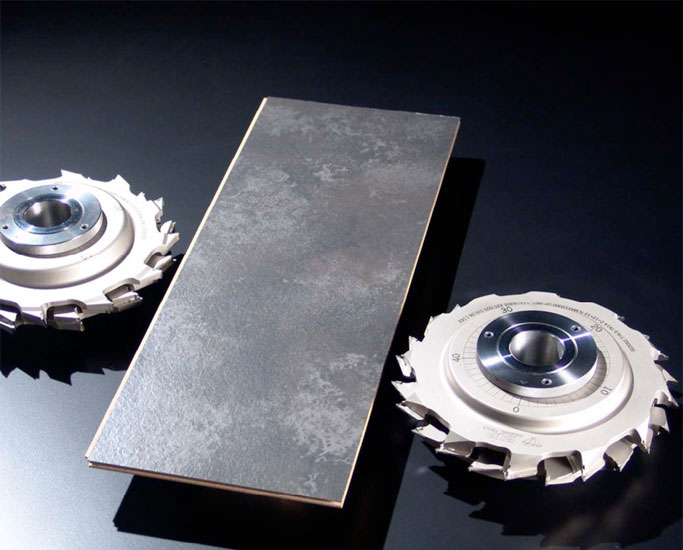

These can be divided into six main groups. Shaped tools with interchangeable knives in HM for profiling wood or MDF panels, for doors or kitchen unit doors on routers and CNC work stations. Shaped and flat diamond tools for boring and sizing of unfinished or finished plastic covered chipboard or MDF panels on routers and CNC work stations.

Cutters and knife-holders or groups of shaped tools with interchangeable knives in HM for moulding machines and tenoning machines which can be used for many types of profiling, and on doors and windows. Group of tools with interchangeable knives in HM for arched windows on numerically controlled cutters. The body of the cutter is made using ERGAL light alloy. Shaped and flat cutters for CNC routers with HM interchangeable blades. Solid carbide spiral tools, which are particularly suitable for cutters needing to cut away large amounts of chip, and at high-speed. These products are very successful both because of their high quality and their efficiency. Their popularity the world over began from a start with local clients. This was a very important moment for them as it allowed them to gain experience from direct contact with their end-users. Today this means that they are always able to come up with the right answer to fit the needs of their clients.

Improve production processes

With the passing of time they have grown from a local company to one working at both a national and international level.

One of the secrets of their success in business on such a wide scale is the speed with which they can produce and deliver. The use of advanced technology helps them to make goods in the shortest of times; thanks also to over 30 skilled workers. This means that the goods go straight to their clients or to their dealers. Their work overseas makes up an important part of their sales and in fact represents 60% of their turnover.

They export to every continent and the main countries they supply are: Russia, Finland, Norway Spain, Australia, New Zealand, England, The Middle East, South Africa, Mexico, Canada and the United States.

Italiano

Italiano